|

Project Description |

Updates |

Our Team |

Media |

References |

Documents

|

| Updates on Our Research |

| Kiln Design and Pyrolysis Modeling: |

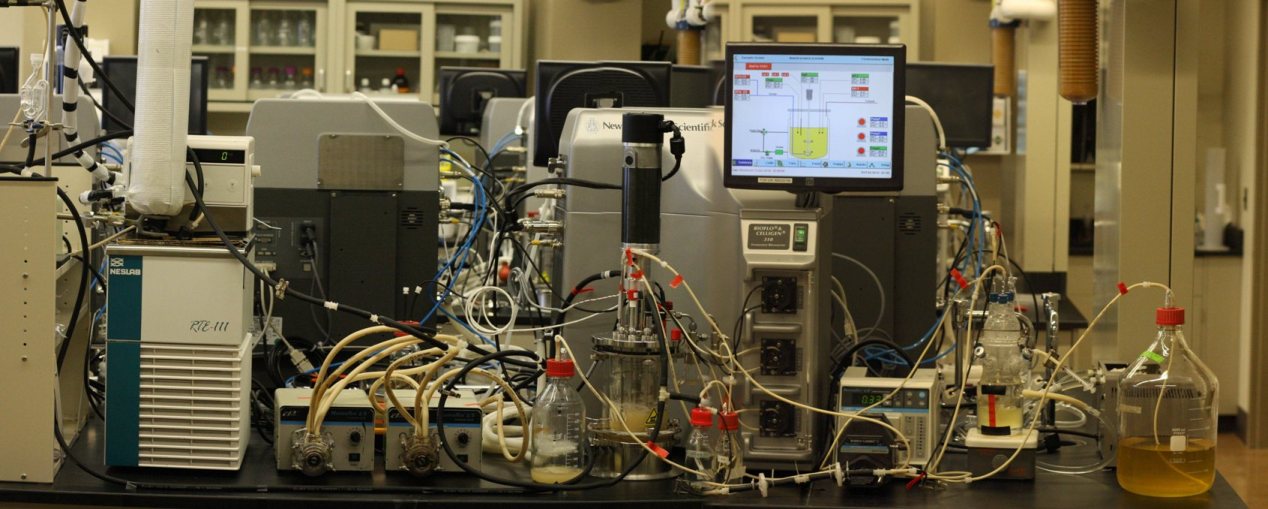

Photo of the newly installed 50 kg/h kiln at Leland Lab, Cornell University |

In conjunction with the company Full Circle, a manufacturer of pyrolysis equipment, we are in the final stages of installing and commisioning a slow pyrolysis kiln that will handle 50 kg biomass feedstock per hour. We will use this kiln to investigate the impact of temperature and feedstocks on biochar and exhaust gas characteristics, and also couple the exhaust gases (syngas) to research to produce biofuels.

Working with the research kiln will allow us to optimize the design of a field-operational kiln for use in Kenya.

Meanwhile, the pyrolysis modeling group in Betta Fisher's lab have been researching pyrolysis processes. Hayet Bennadji and coworkers recently submitted an extended abstract highlighting their work on chemical and physical processes in pyrolysis of woody biomass. Krystle Smith is developing a numerical model of wood pyrolysis that will be tested against the experimental results reported in the abstract. The model incorporates the kinetic mechanism developed by Eliseo Ranzi's group in Milan. Shaka Shabangu is investigating the tar cracking components that will be needed in a pyrolysis kiln to complete the conversion of non-biochar carbon to precursors for biofuel fermentation. With Hanno Richter and Steve Vanek, he is also developing an overall mass balance and sensitivity analysis of the pyrolysis and biofuels fermentation process that will identify constraints and set targets for biofuel production.

|

| Pyrolysis Gas to Butanol Conversion |

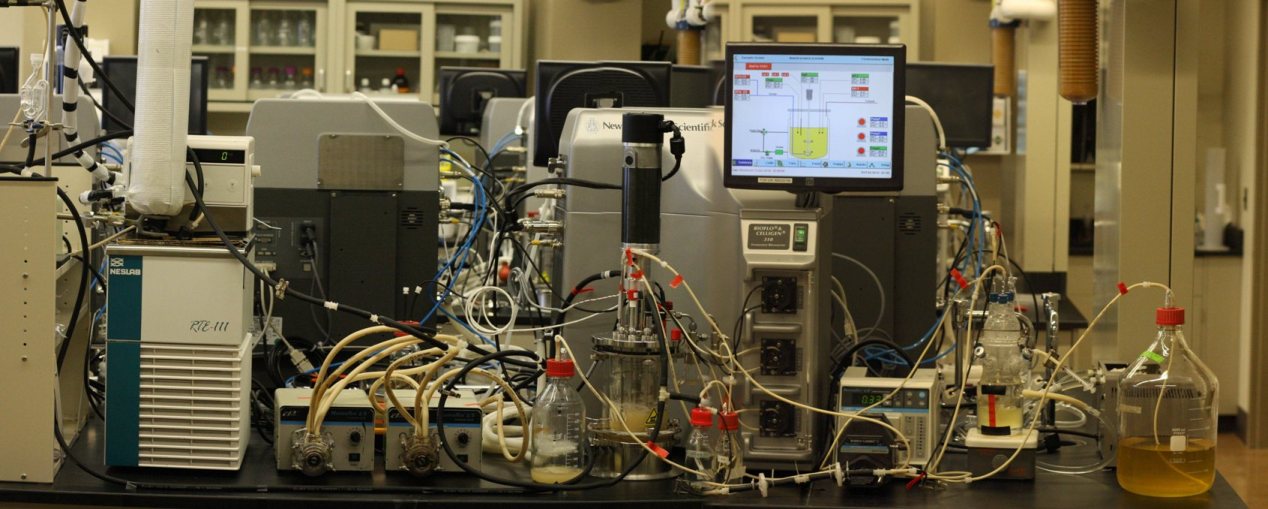

Photo: fermentation flask for conversion of precursors to Butanol by microbes (L. Angenent) |

We are continuing our research of conversion of potential gases from pyrolysis to butanol. The first goal is to make butanol from simple precursor gases that would be part of the exhaust gases from pyrolysis and biochar production.

The Angenent lab has been working to increase the production efficiency of biofuels and has recently assembled a 100 liter stainless reactor for eventual connection to the pyrolysis kiln output and fermentation of syngas to alcohol for fuel use. As part of this effort, Hanno Richter has been optimizing syngas reactor design and operating parameters to improve the efficiency of syngas to alcohol fermentation. He improved mass transfer, energy efficiency, carbon recovery in ethanol, ethanol concentration, and output rate. Miguel Perez is investigating the conversion of carboxylic acid precursors to alcohols (propanol, butanol, hexanol). |

| Economic Impacts, Feasability and Sustainability Analysis |

Photo: Cornell and ICRAF team visits a smallholder household during bean harvest and cleaning in summer 2010. |

Planning is underway for household and community-based research work to gather economic baseline information for the study, in conjunction with the biomass resource assessment (below). The study will be started by Julia Berazneva, Frank Place, David Lee, and other research staff during summer 2011 in Kenya. |

| Biomass Assessment, Biochar Characterization and Soil Impacts |

Photo: fuelwood is one of the existing uses for biomass in the region. |

Planning is underway for a biomass resource assessment in the area around Kisumu, Kenya where the project is based. Estimating total amounts and locations of potential feedstocks is an important step in assessing the amounts of biofuel and biochar that could be produced and the sustainability of this production. The resource assessment will be conducted in January 2011 by Dorisel Torres and research staff from our collaborators at the World Agroforestry Center (ICRAF). |

Photo: close association of root and root hairs with a piece of wood char. |

The Lehmann lab continues its efforts in characterizing char quality related to feedstock and temperature of production. We find depending on just these two variables, chars can be produced with a wide variety of characteristics such as ash (mineral) content, pore size, and pH.

David Guerena recently completed a trial testing the influence of biochar feedstocks, production temperatures, and post-treatments on biological nitrogen fixation in beans. He is currently conducting laboratory analysis on the trial and planning for a follow-up trial looking at the interaction between biochar application and native soil fertility on biological nitrogen fixation.

More information: Lehmann Lab website |